The science behind DURA+

Conventional adhesives and silicone sealants have been around for decades. They do the job well, and are relied upon by hundreds of trade professionals on a daily basis.

But as the construction industry becomes ever more competitive and fast-paced, and as tradesmen strive to do more work in less time, there’s demand for a new generation of adhesives and sealants that help them to work more efficiently. That’s where DURA+ comes in.

But what makes DURA+ different from other cartridge products like sealant, caulk, mastic and adhesive? Why is it more efficient – and is it really better? Let’s look at some of the science behind DURA+, and its benefits for the end user:

Firstly, what exactly IS DURA+?

DURA+ is a hybrid polymer compound, also sometimes known as a modified polymer compound. These compounds are most often compared to silicone since they have the same consistency, are applied in the same way, and can be used for many of the same tasks.

But the main difference between DURA+ and conventional silicone is that it doesn’t actually contain any silicone at all. Instead, it’s made from modified polymers that have many of the same properties, as well as several additional benefits (and none of the drawbacks).

So what’s a modified polymer and what does it do?

In the case of adhesives or sealants, a polymer is a synthetic substance formed from long chains of molecules that are chemically bonded together. We can modify these chains using other chemicals to change the properties of the final material.

In the case of DURA+, the base polymer is modified using chemical compounds called silyls. These compounds promote durable bonds due to their coupling and cross-linking action. They allow DURA+ to stick to a wide variety of materials, including those that are resistant to adhesion such as glass and lead. Silyls are also hydrophobic, which means they repel water – this is why DURA+ is so effective at sealing leaks and repairs in wet conditions or even underwater.

Why is this better?

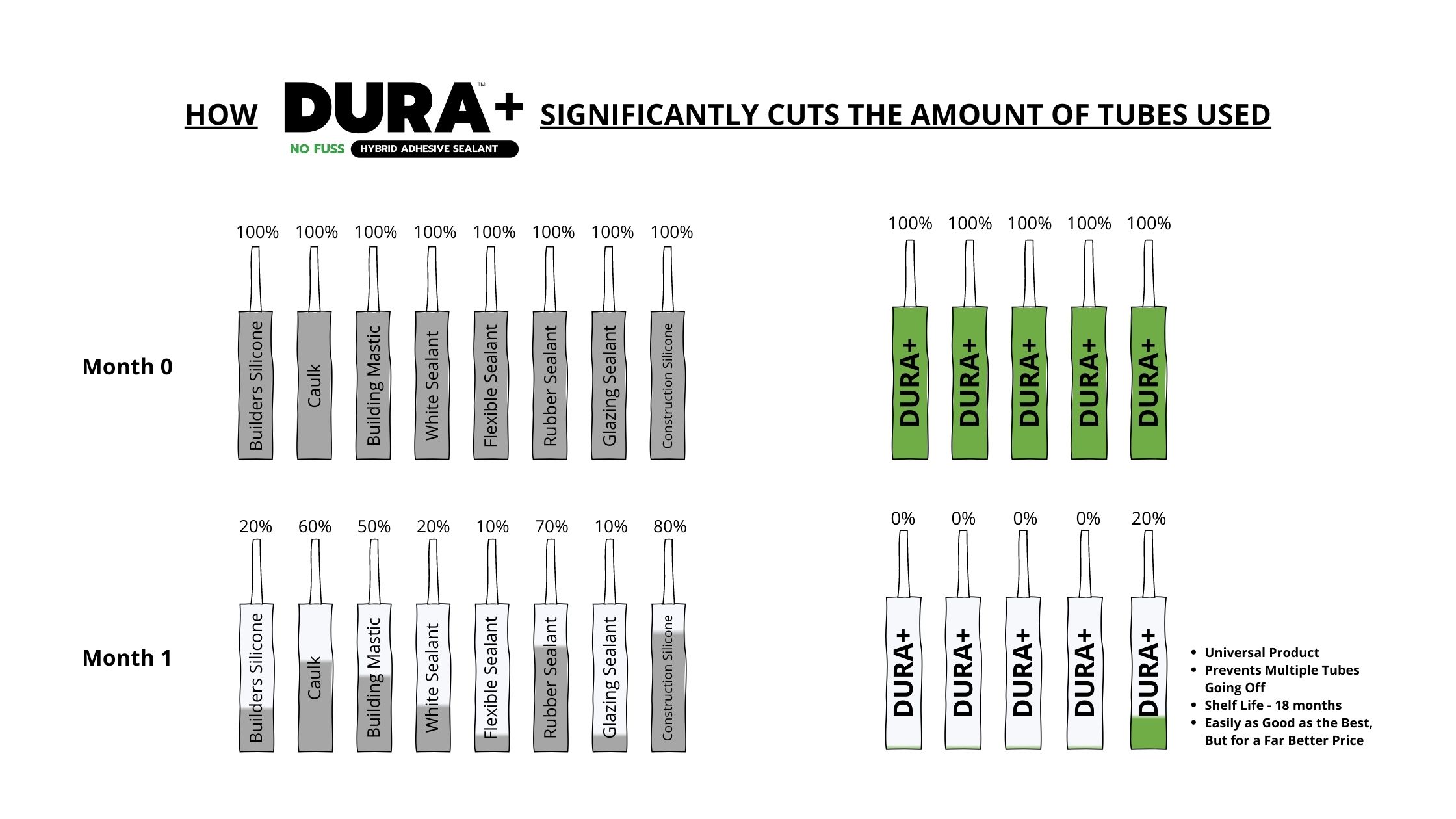

The formulation of DURA+ means it’s a multi-purpose product, so it can replace many of the cartridges tradespeople have to carry around for different jobs. For instance, you can’t use silicone as an adhesive because it doesn’t ‘grab’, it takes a long time to dry and it’s not very strong. You can’t use adhesive as a sealant, because it’s not flexible or water repellent. But with DURA+, you get all these properties in a single product.

OK, so what else can it do?

As well as their high grab, high strength bonds and water-resistant performance, modified polymers have a number of other properties that make them really useful for a wide range of construction and repair tasks.

1. They are extremely elastic.

Due to its unique composition, a bead of DURA+ can be stretched to four times its length without breaking, and this elasticity is not impaired even by exposure to harsh conditions. This makes DURA+ an ideal solution for outdoor repairs, for bonding flexible materials like lead or plastic, and for environments where vibrations or movement are a challenge, such as marine repairs.

2. They are solvent-free.

DURA+ does not rely on solvent for its curing process. This means it is low VOC and low odour, as well as being environmentally non-toxic. In fact, DURA+ is so safe, it’s approved for use in food preparation areas and won’t harm aquatic life (perfect for fixing a leaky fishpond). Another big plus of being solvent free is that DURA+ can be used to bond and seal natural stone, and unlike conventional silicone, won’t cause unsightly solvent staining.

3. They require minimal surface prep

As a modified polymer, DURA+ is made from molecules that are known for their ability to grab onto almost any surface, and then form even more interlinked bonds as they cure. This means you can use DURA+ on almost any surface without the need for surface prep – no sanding, no priming, no need to even dry off.

4. They don’t shrink or slump

DURA+ has a high degree of slump resistance, making it ideal as a gap filler for holes and cracks. It forms a skin in around 10 minutes and once dry, it won’t shrink or split, even under stress.

5. They are resistant to heat, cold and chemicals

DURA+ can be used in temperatures as low as -40°C and as high as +120°C. It’s resistant to a wide range of chemicals, making them suitable for use in industrial, biochemical and food processing settings as well as domestic or clinical environments.

Hybrid polymer products like DURA+ eliminate the need for a large number of ‘specialist’ adhesives, sealants, mastic and caulk. As illustrated, one product can be used for a wide array of tasks, from simple domestic repairs to professional installations and emergency fixes in challenging environments.

To find out more about the properties of DURA+, get in touch!